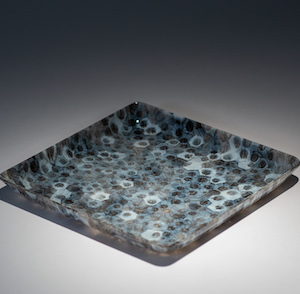

Pressed Trays

The other day I found documentation of my first attempts at pressing or compressing glass between kiln shelves….from 2012! It has taken a while but the process is definitely dialed in at this point. Read on…..

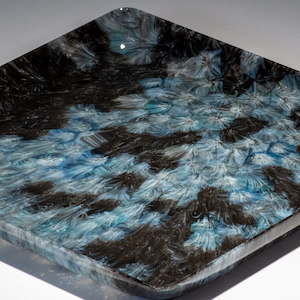

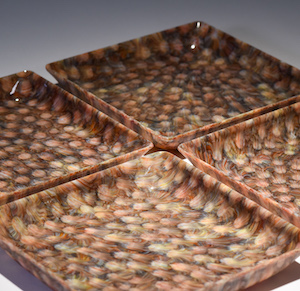

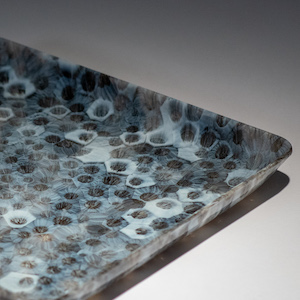

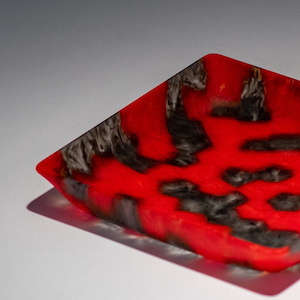

Kilnformed glass has a reputation for being 6mm or a quarter-inch thick…..or thicker. What about thinner? Some might say it’s too fragile. This is not the case! Students in this workshop will explore OnGrade Studio’s process of making personalized sheet glass from Vitrigraph cane while learning from Nathan. The unique sheet will then be transformed into refreshingly (and uniformly) thin, lightweight and functional trays via the Dropout process. The methods presented during this workshop can easily be adapted to produce many different design effects as well as vessels, including deeper ones. Dropout Vessels will be thoroughly discussed via demonstrations and discussions. Prospective students should be willing to work hard and be challenged while learning.

The other day I found documentation of my first attempts at pressing or compressing glass between kiln shelves….from 2012! It has taken a while but the process is definitely dialed in at this point. Read on…..

Kilnformed glass has a reputation for being 6mm or a quarter-inch thick…..or thicker. What about thinner? Some might say it’s too fragile. This is not the case! Students in this workshop will explore OnGrade Studio’s process of making personalized sheet glass from Vitrigraph cane while learning from Nathan. The unique sheet will then be transformed into refreshingly (and uniformly) thin, lightweight and functional trays via the Dropout process. The methods presented during this workshop can easily be adapted to produce many different design effects as well as vessels, including deeper ones. Dropout Vessels will be thoroughly discussed via demonstrations and discussions. Prospective students should be willing to work hard and be challenged while learning.

If you are new to glass working, one thing that will be abundantly clear after class is how much of an investment in time and money kiln-glass can be. Tools and materials are not inexpensive and there are many that are necessary for success. The facilities at OnGrade Studio are available to rent if you need a place to work after class. Alternatively, you can apply your new and/or refreshed skills to kiln-glass projects in your personal studio. I’m happy to discuss home studio setup during our time together in the studio.