Kiln-cast Glass

Basically, the process of filling a void with glass. Kilncast glass can take many forms and require a variety of processes. Entry level kiln casting usually starts with clay as a modeling material. A kiln-worthy, plaster-silica based, investment mold is then made over the model. Ultimately the model material is removed and the void is filled with hot glass in the kiln. Molds are usually in the kiln for 36 hours or more.

Lost-wax kiln casting is a bit more involved and, as the name implies, the artist uses wax to produce models which are then invested. The wax is eventually melted out of the way, revealing a cavity that is ready to accept the glass.

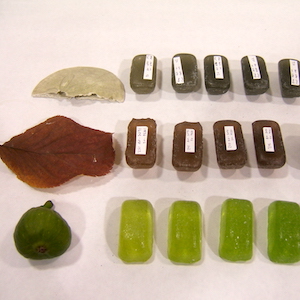

Assembled mold making refers to the process of using vermiculite board to assemble a mold that can go into the kiln. This is usually a very simple mold used to cast rectilinear forms or a simple geometric shape. Vermiculite board molds can be used repeatedly….unlike traditional plaster/silica based molds.

Basically, the process of filling a void with glass. Kilncast glass can take many forms and require a variety of processes. Entry level kiln casting usually starts with clay as a modeling material. A kiln-worthy, plaster-silica based, investment mold is then made over the model. Ultimately the model material is removed and the void is filled with hot glass in the kiln. Molds are usually in the kiln for 36 hours or more.

Lost-wax kiln casting is a bit more involved and, as the name implies, the artist uses wax to produce models which are then invested. The wax is eventually melted out of the way, revealing a cavity that is ready to accept the glass.

Assembled mold making refers to the process of using vermiculite board to assemble a mold that can go into the kiln. This is usually a very simple mold used to cast rectilinear forms or a simple geometric shape. Vermiculite board molds can be used repeatedly….unlike traditional plaster/silica based molds.

If you are new to glass working, one thing that will be abundantly clear after class is how much of an investment in time and money kiln-glass can be. Tools and materials are not inexpensive and there are many that are necessary for success. The facilities at OnGrade Studio are available to rent if you need a place to work after class. Alternatively, you can apply your new and/or refreshed skills to kiln-glass projects in your personal studio. I’m happy to discuss home studio setup during our time together in the studio.